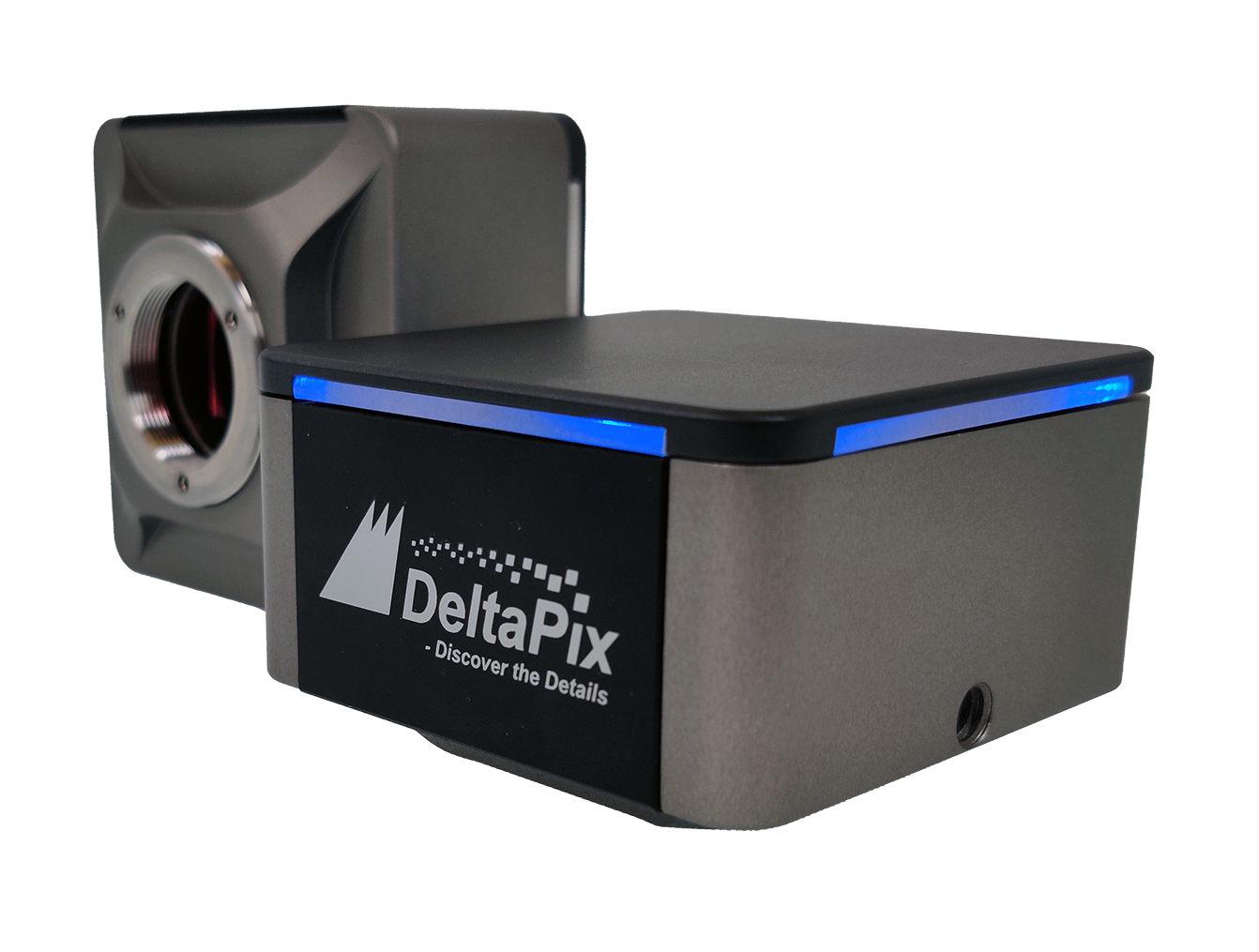

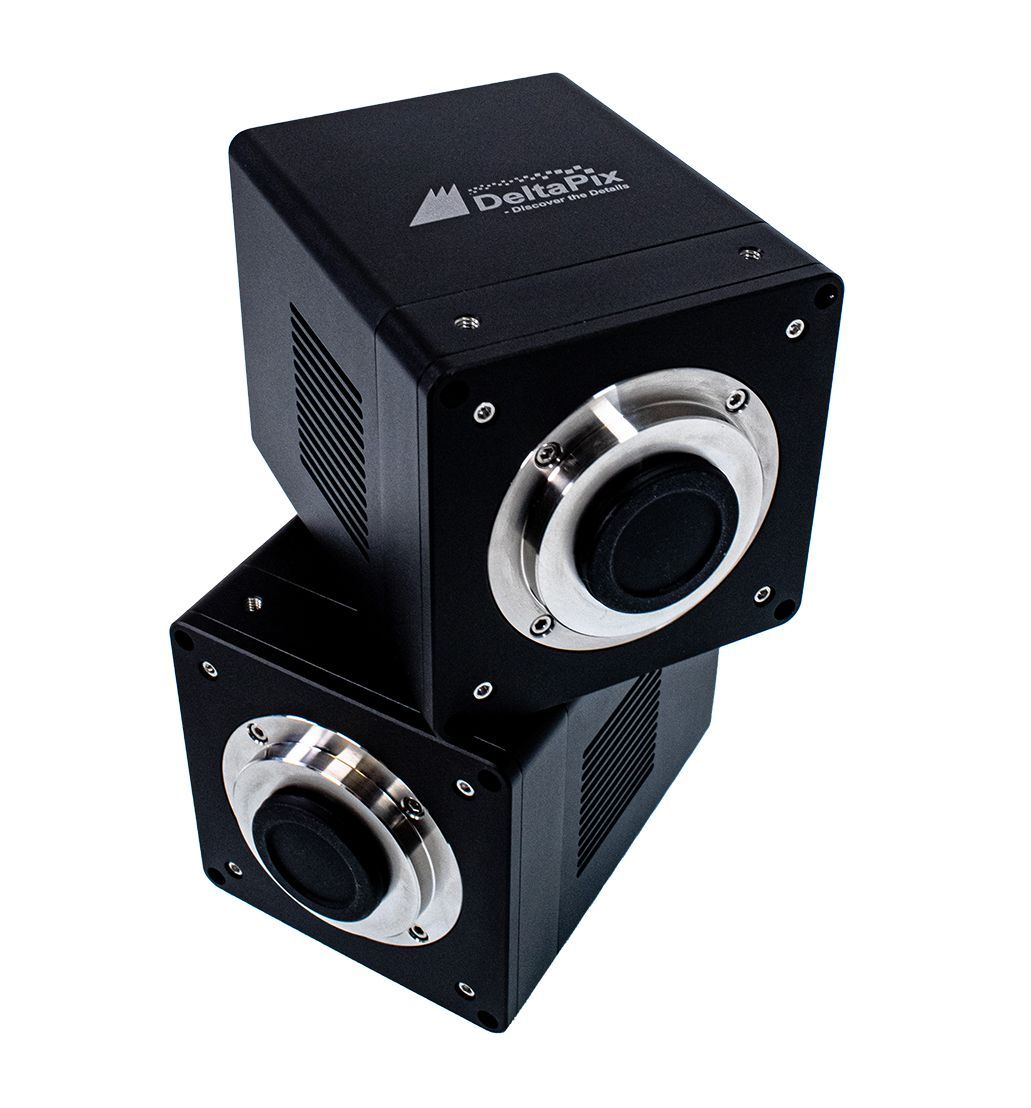

DELTAPIX INVENIO Series

DELTAPIX COOL Series

DELTAPIX SWIR Series

DELTAPIX HDMI Series

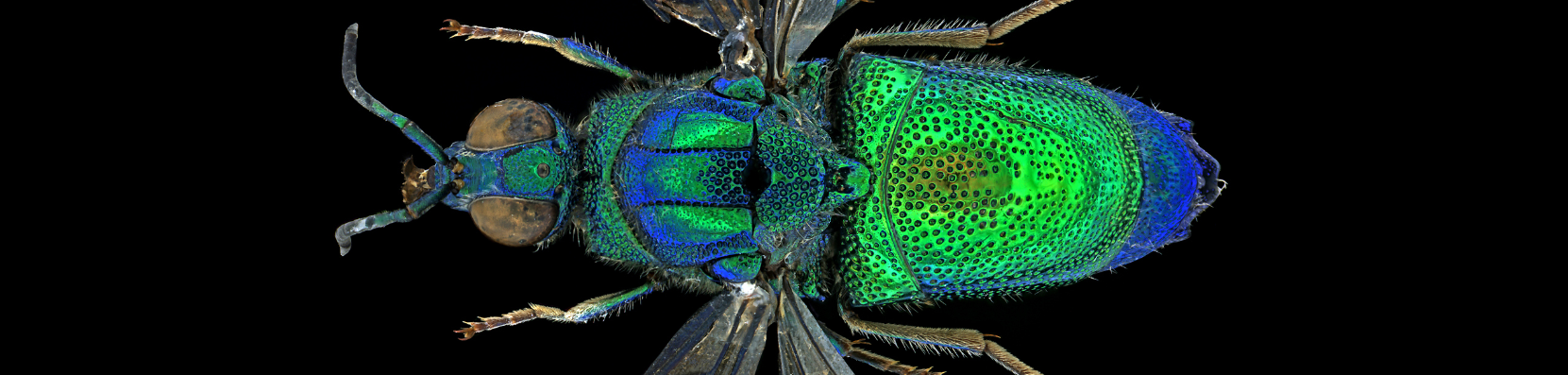

DELTAPIX microscope cameras

The DeltaPix range of microscope cameras is intended for all types of microscopy users, from the basic routine user to the advanced professional investigator who needs to manipulate the camera's working method and control every detail.

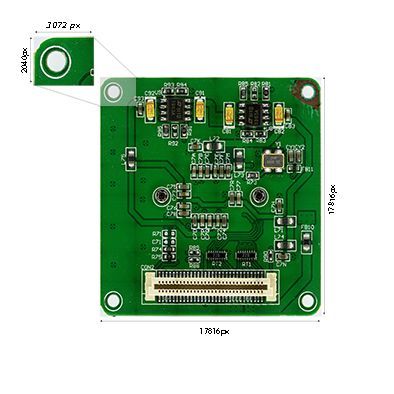

The Invenio camera range is a series of easy-to-use cameras with high resolution, high sensitivity and very low noise. All DeltaPix cameras are manufactured to scientific standards with an extreme focus on detail; Assembled in a dust free environment, with high quality IR filters, high quality sensors, low temperature design and long durability.

All DeltaPix cameras are equipped with the latest high-quality CMOS and Exmor™ sensors.

General features and specifications

InSight Basic

Microscope software

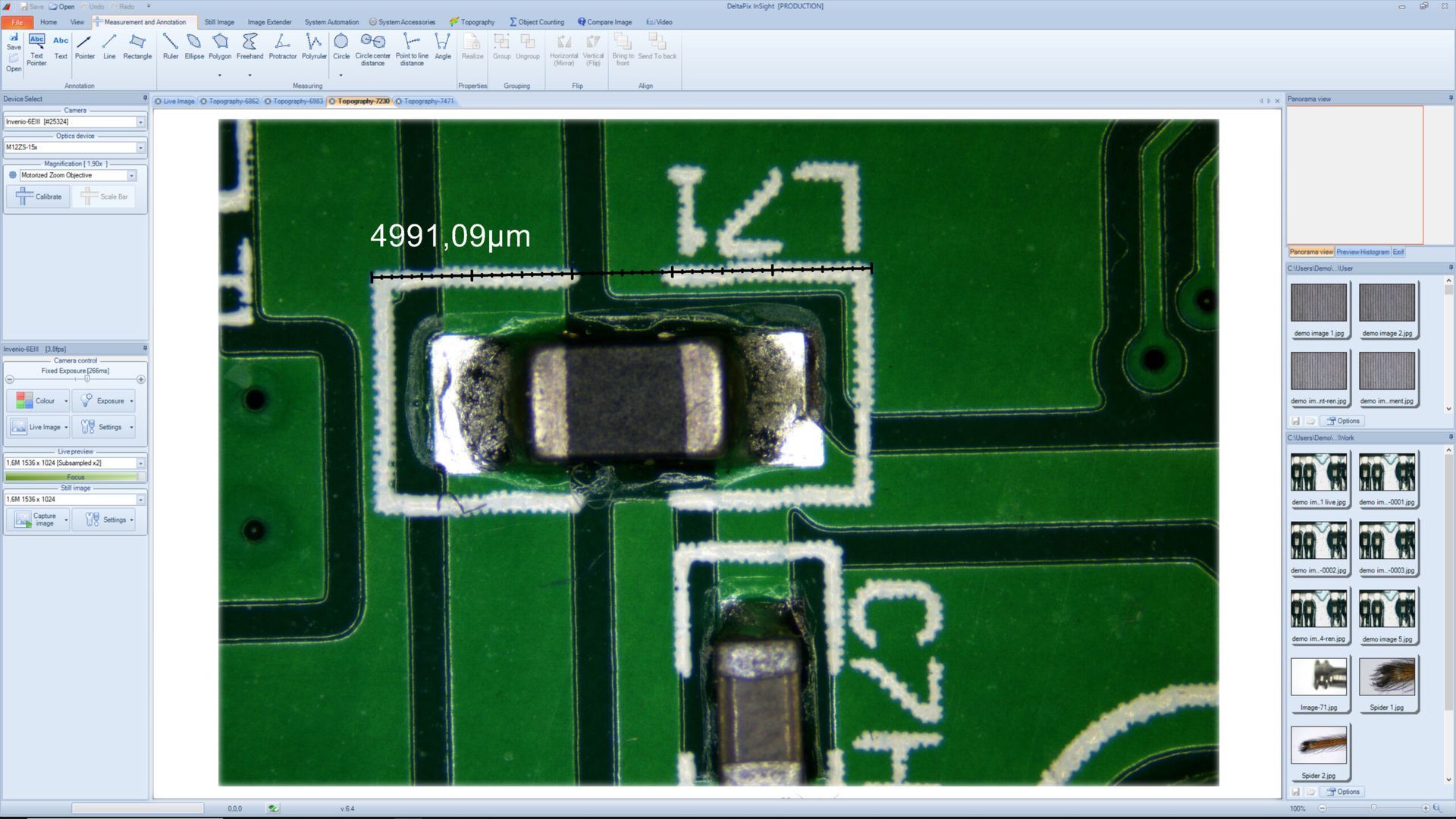

Modern user interface

DeltaPix InSight has a modern and intuitive user interface based on the familiar ribbon style from Microsoft Office 2010/2016. The functions have been logically grouped and the program is easy to use. DeltaPix InSight is modular software allowing the operator to purchase modules as needed, making DeltaPix InSight highly efficient and affordable.

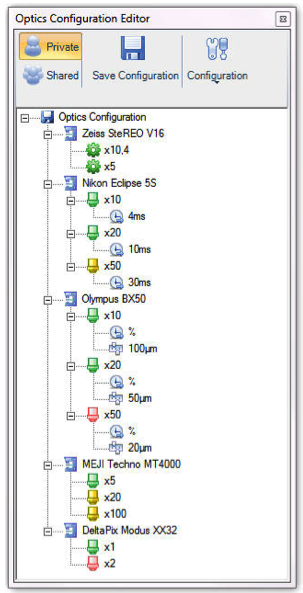

Calibration

Each optical device, objective and camera can be calibrated individually. In this way, multiple microscopes and other optical systems can be managed through the same software installation. Calibrations can be private or shared among all users of the computer.

Measurement and annotation

Measurement and recording are important parts of any quality control process. Get accurate reproducible results through a variety of features found in DeltaPix InSight:

• Ruler

• Ellipse

• Conveyor

• Circle of three points

• Distance to the center of the circle

• Distance point to line

Measurements

Measurements can be made on still images or directly on the live camera image. The measurement precision and unit of measurement can be selected individually. A scale bar can be automatically inserted into images. By calibrating the optics in high resolution mode, accuracy to fractions of a µm can be achieved. For each lens, the preferred depth of field and fixed or relative exposure time can be defined.

ReportsMeasurement results and images can be easily exported to a Microsoft Excel spreadsheet. This allows further data processing in a flexible way. Also, the report can be automatically converted to a PDF report. The reports do not require the installation of Microsoft Excel or a PDF writer. Measurement data from multiple objects can be aggregated into a comma-separated flat file for statistical use.

Minimum system requirements

UPC

Intel I5 (quad core)

RAM

8GB

disk space

15GB

Operating system

Windows 10 and Windows 11 64-bit version

Monitor

Full HD (1920 x 1080)

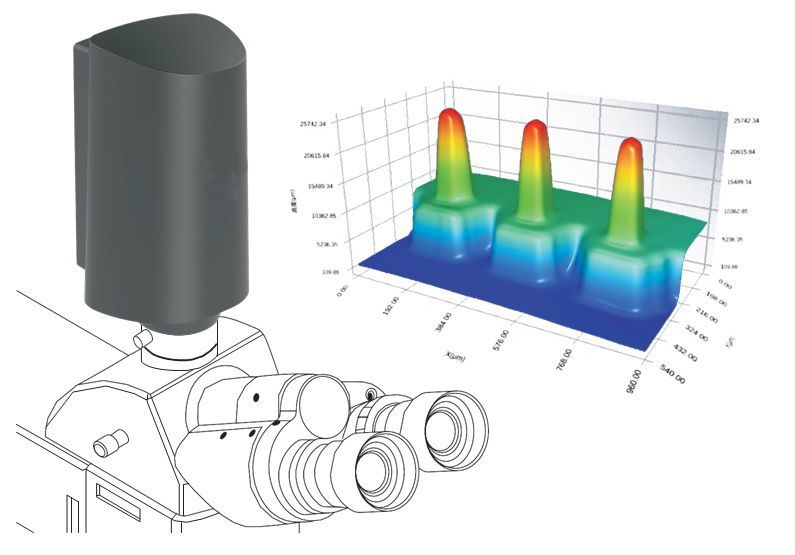

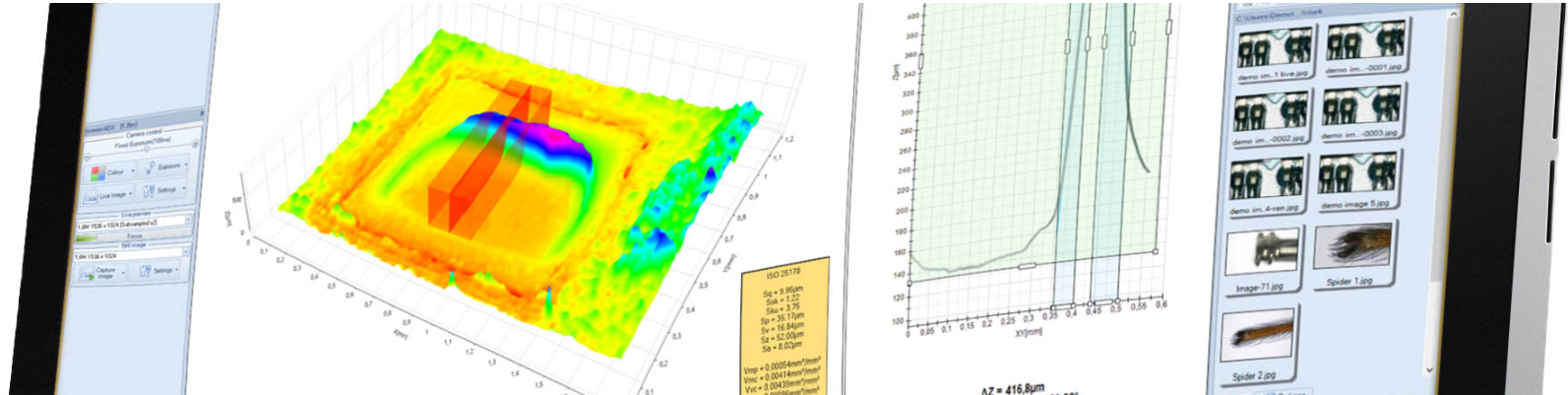

Extended focus

Exposure and manual sewing

InSight has a state of the art extended focus feature. Both manual and automatic extended focus is possible. The auto function uses focus motor automation. The extended focus function can combine images with different levels of focus into a single sharp image.

Extended ExposureInSight Basic includes a state-of-the-art Extended Exposure feature. The extended exposure function can combine images at different exposure times and combines the images into a single perfectly exposed image.

StitchingWith its intuitive user interface, automatic and manual stitching of individual captured images can be done quickly and accurately with DeltaPix InSight.

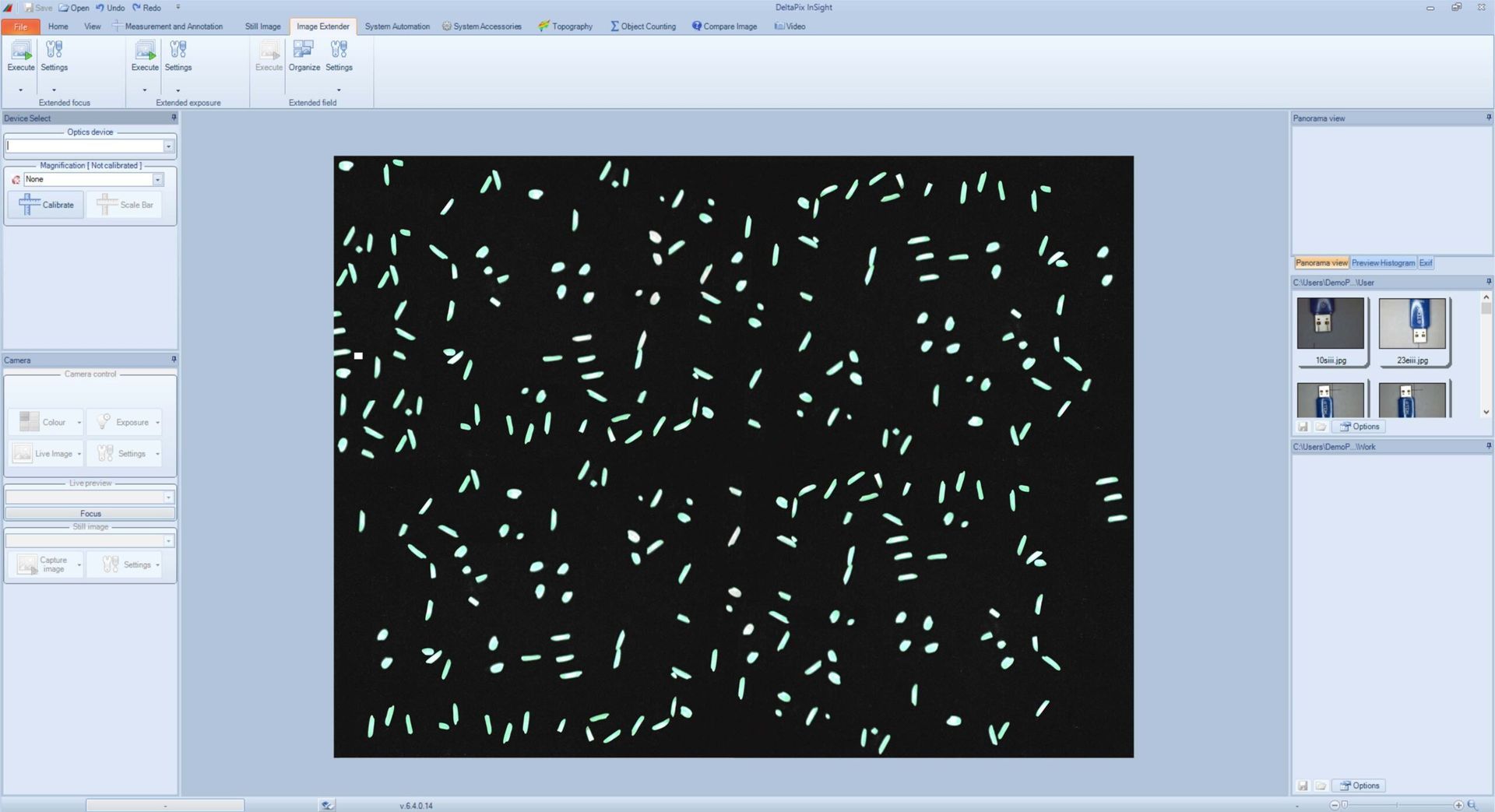

Segmentation, counting and multiphase analysis

The multi-phase counting module can use up to four phases. A counting phase is defined by a set of characteristics, such as RGB color gamut and geometric features.

Pre-processing operations can be performed using morphological dilation or erosion operations.

Batch counts

This feature makes scanning and counting objects in large regions fast, objective, and simple.

Scanning of large regions is done automatically by setting opposite corners on the region. After this, capturing and saving the image is done with ease. Counting can be done automatically after the scanning process or later as a batch count of images in a directory.

Adaptive Threshold is especially suitable for detecting and counting small particles.

Unlike global thresholding, where a single threshold value is used to divide an image into two regions based on pixel intensity, adaptive thresholding uses a local threshold value that is computed for each pixel in the image based on the characteristics of its neighboring pixels. This allows adaptive thresholding to handle images with different lighting conditions, as the local threshold adjusts to account for these variations.

There are several methods for adaptive thresholding, including mean thresholding and Gaussian thresholding. Each method uses a different approach to calculate the local threshold value and has its own strengths and weaknesses. The choice between Gaussian and mean thresholding for adaptive thresholding depends on the characteristics of the image being processed and the specific requirements of the application. In general, Gaussian thresholding is more efficient when dealing with images that have uneven illumination, since it uses a weighted average of the pixel intensities of each pixel. This means that the Gaussian threshold gives more weight to pixels closer to the center of the neighborhood and less weight to pixels farther away, helping to account for any lighting variation.

After segmentation, basic morphological operations can be applied.

Finally, parameters such as object area, Feret object min and max, and M1 can be used to include or exclude counted objects.

The result is presented as a single count or as a count/cm².

The multi-image counting result can be automatically exported to an Excel report.

Measurements

Measurements can be made on still images or directly on the live camera image. The measurement precision and unit of measurement can be selected individually. A scale bar can be automatically inserted into images. By calibrating the optics in high resolution mode, accuracy to fractions of a µm can be achieved. For each lens, the preferred depth of field and fixed or relative exposure time can be defined.

Object discrimination can be performed using the area of geometric features, M1, and the minimum/maximum Ferret distance. The geometric characteristics can be:

Individual for each phase. This makes it possible to count objects with different geometric characteristics.

This means that all phases use the same geometric characteristics. Used when counting objects only segmented by color. For multiphase counting, a percentage of the area of each object is calculated, making multiphase percentage calculations easier.

Setup is easy and intuitive with interactive false color marking of counted objects and an indication of rejected objects.

The count result can be exported to an Excel spreadsheet for further processing and analysis. The Excel Report Builder does not require Excel to be installed.

PDF reports can also be generated directly.

All settings can be saved in a dedicated workspace, making switching between different counting scenarios quick and easy.

Microscope and stage interface

The interface module can connect to a variety of motor controllers (eg Prior, Märzhauser, Ludl, Zeiss via MTB server) and can even control a combination of them.

APPLICATIONS