Materials science

Materials Science is a field which deals with the discovery and development of new materials and methods for their study. It is a multidisciplinary science involving different fields of knowledge such as physics, chemistry and engineering. Materials Science focuses on studying the most important characteristics of materials such as their mechanical, chemical, electrical, thermal, optical and magnetic properties. The field can be sub-divided into different disciplines including nanomaterials, organic materials, electronic/photonic materials, structural/composite materials and smart materials.

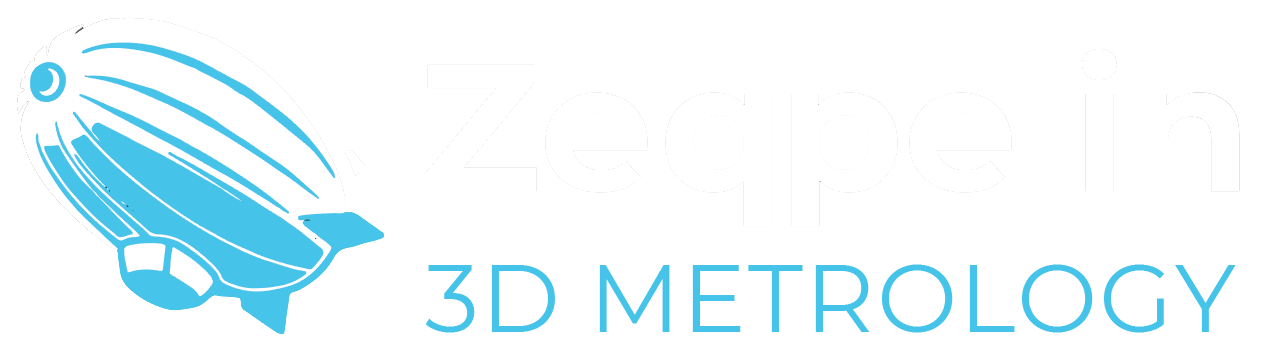

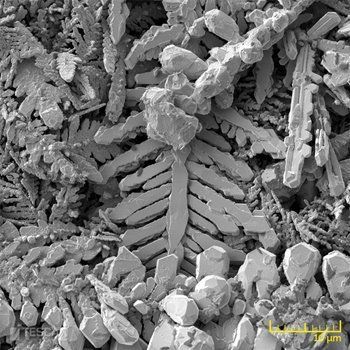

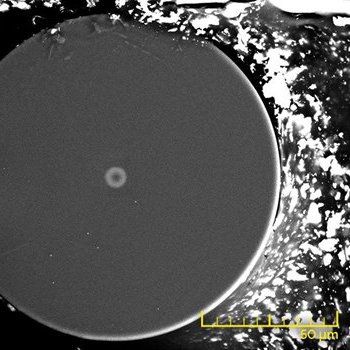

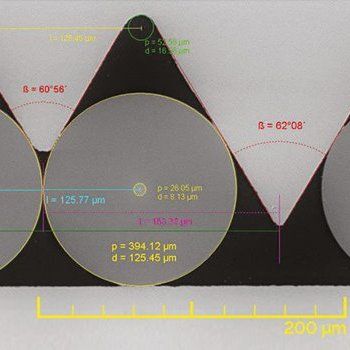

Steels and metal alloys

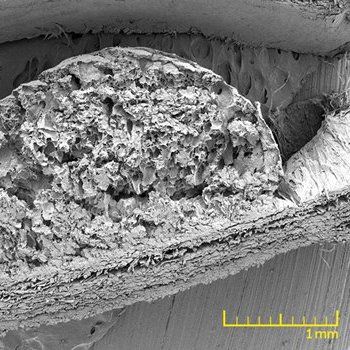

High resolution and large depth of focus are the main functions which make scanning electron microscope (SEM) a great tool for observing topographic features of samples made of steel and metal alloys.

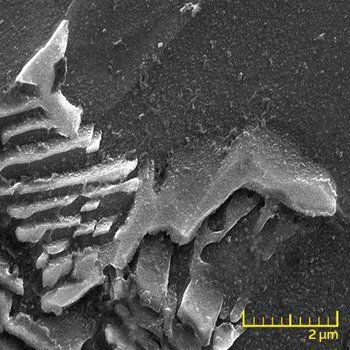

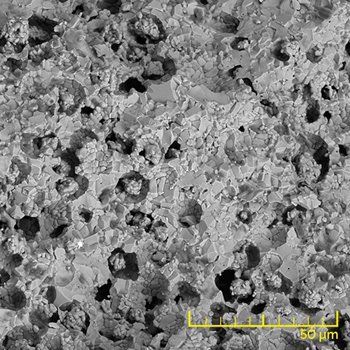

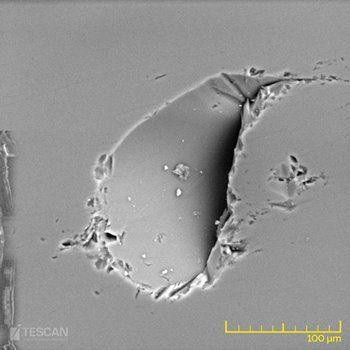

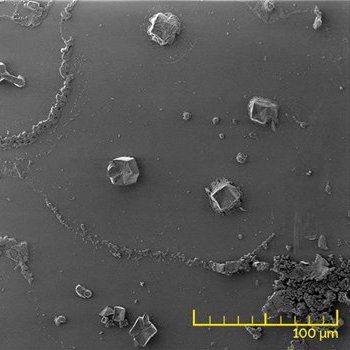

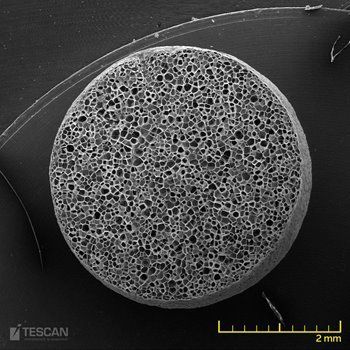

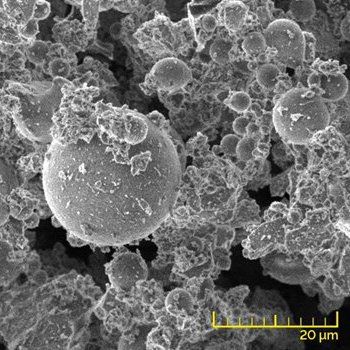

Ceramics and hard coatings

Uncoated and non-conducting samples can be observed in the variable pressure mode without damaging the sample. Components made of ceramic materials are in some cases the only solution to technical problems that cannot be resolved with conventional materials.

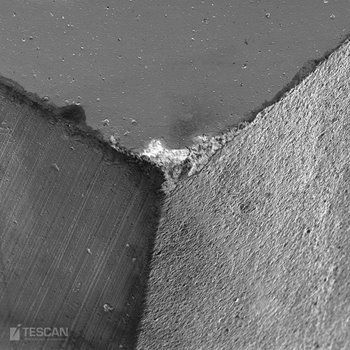

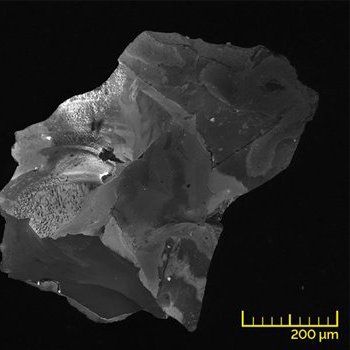

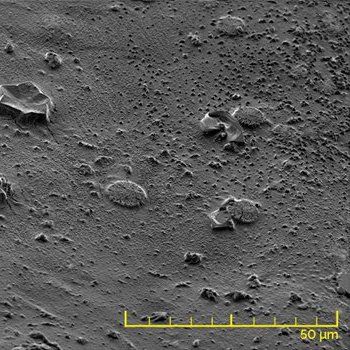

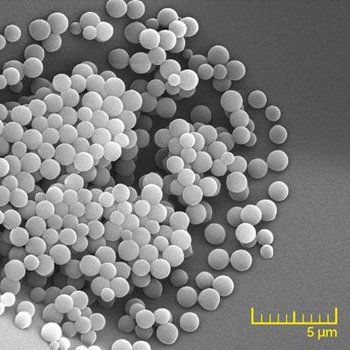

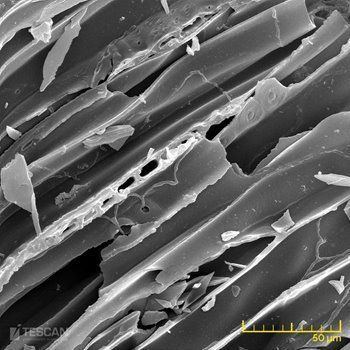

Glass

TESCAN SEMs are of great benefit to the glass industry. Glass and its derived products are an important part of automotive, construction, engineering and energy industry, among others.

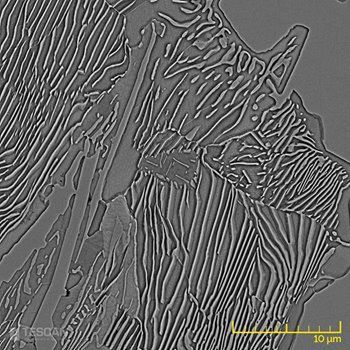

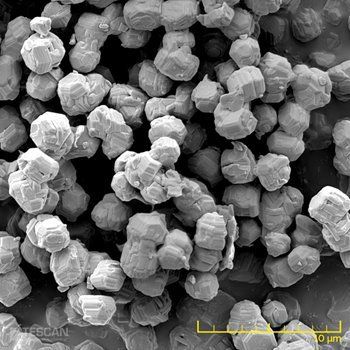

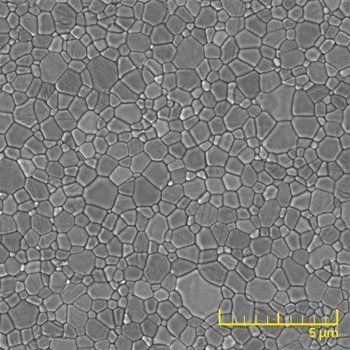

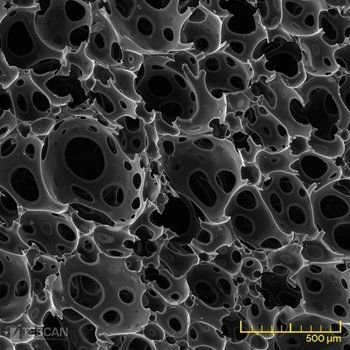

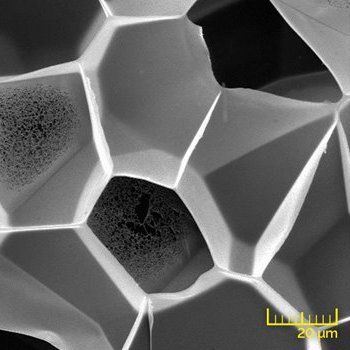

Polymers and Composites

High resolution and large depth of focus are capabilities that make TESCAN SEMs excellent instruments to observe polymers, plastic and other composite materials.

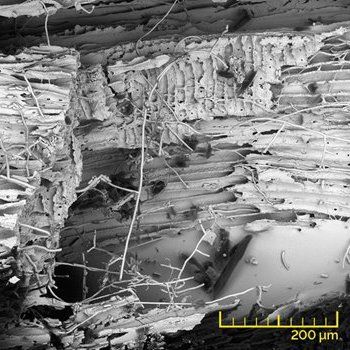

Material for building and civil engineering

Scanning electron microscopy has been an essential analytical technique for studying a variety of construction materials.

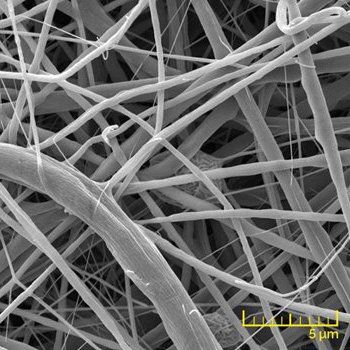

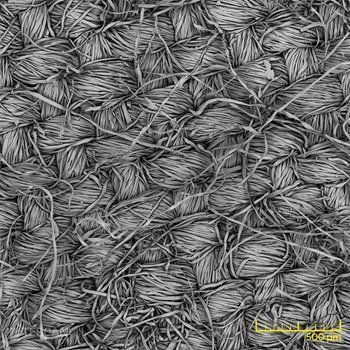

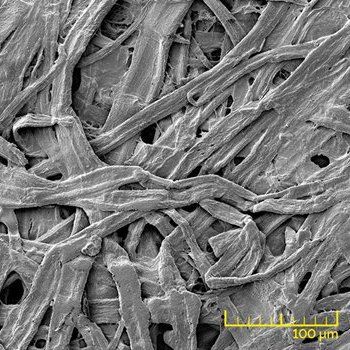

Wood, Textile and Paper

Scanning electron microscopy has been an essential analytical technique for studying a variety of construction materials.