Ciencia de materiales

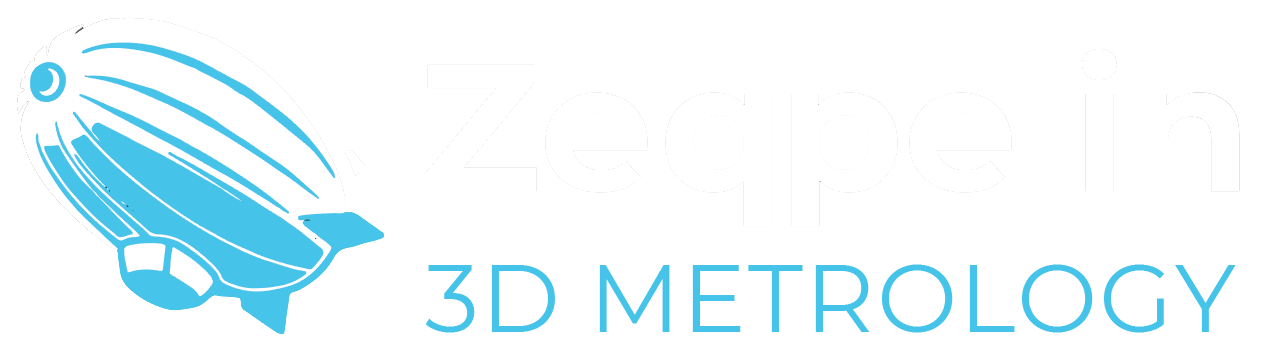

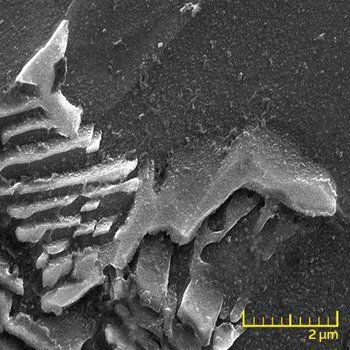

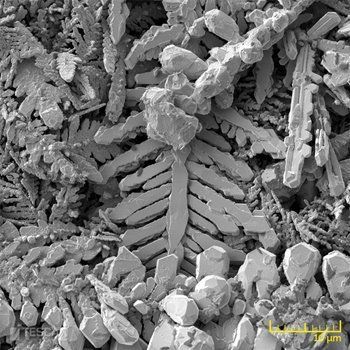

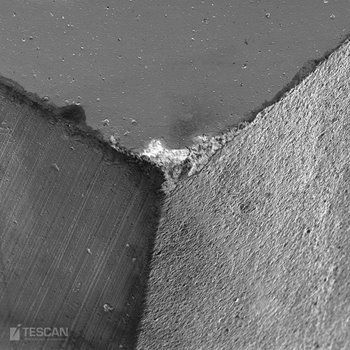

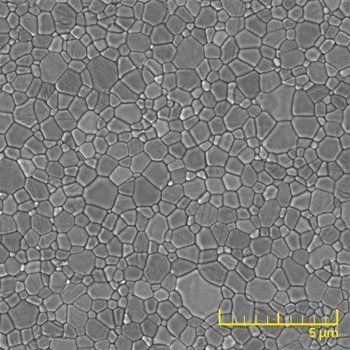

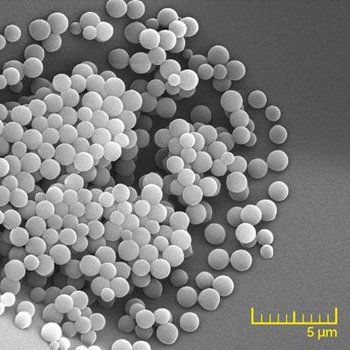

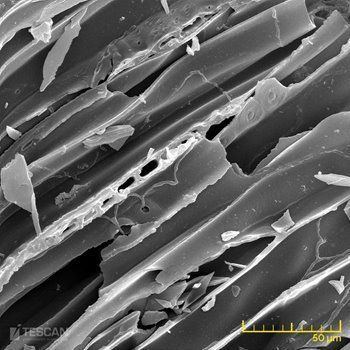

Aceros y aleaciones metálicas

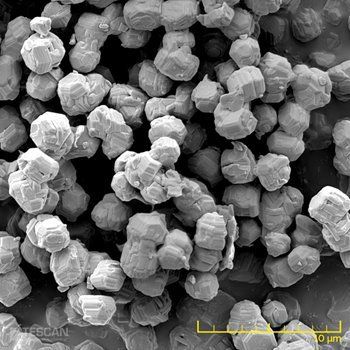

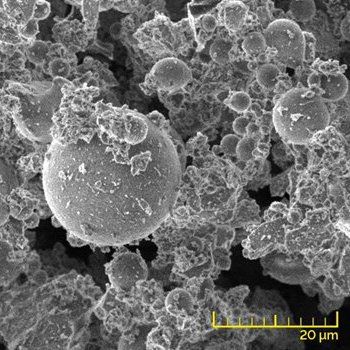

Cerámica y revestimientos duros

Vidrio

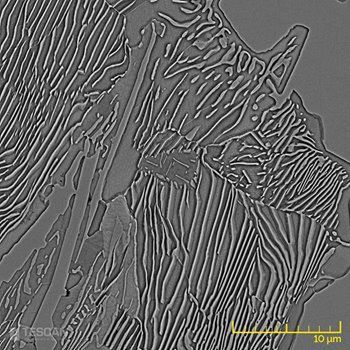

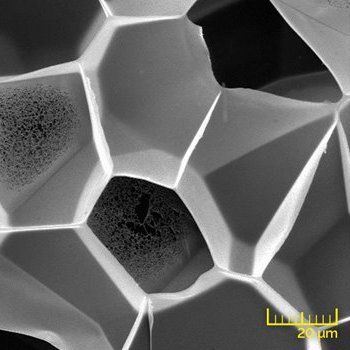

Polímeros y Compuestos

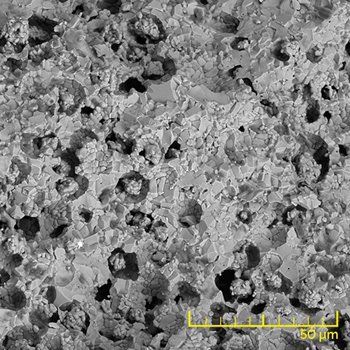

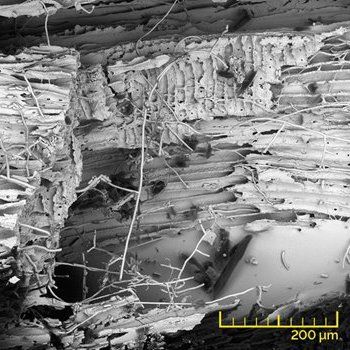

Materiales construcción e Ingeniería civil

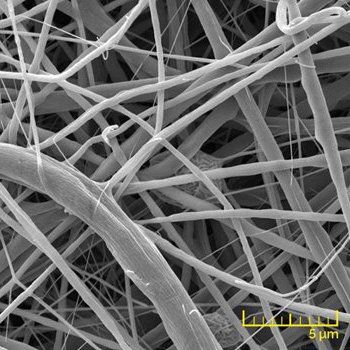

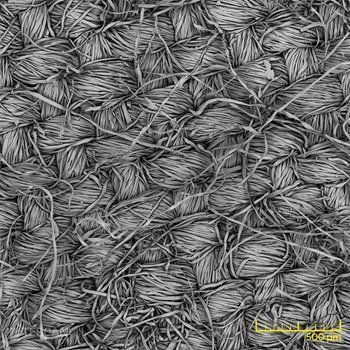

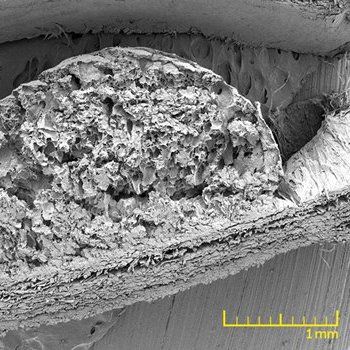

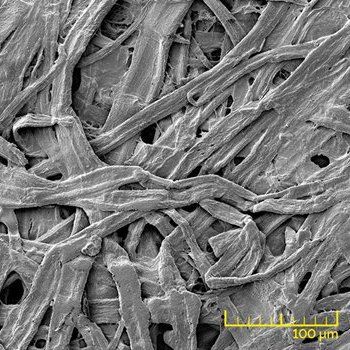

Madera, Textil y Papel

Equipos TESCAN para CIENCIAS DE MATERIALES

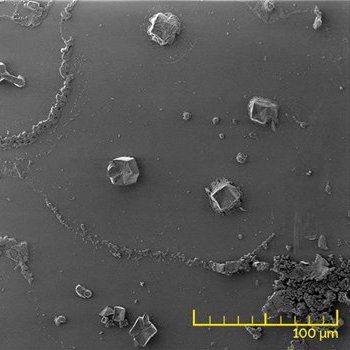

TESCAN VEGA 4

SEM analítico para aplicaciones rutinarias de caracterización de materiales, investigación y control de calidad a escala micrométrica.

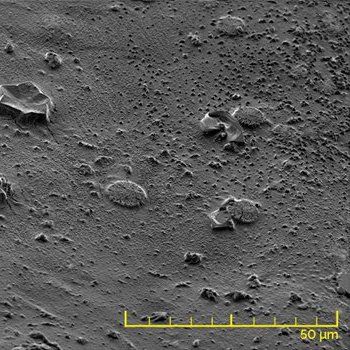

TESCAN MIRA 4

SEM analítico de alta resolución para aplicaciones rutinarias de caracterización de materiales, investigación y control de calidad a escala submicrónica.

TESCAN CLARA

Crio-SEM UHR versátil para la caracterización de sus muestras biológicas y otras muestras sensibles al haz

TESCAN MAGNA

Imágenes avanzadas de UHR SEM y STEM para la caracterización de sus muestras biológicas y sensibles al haz

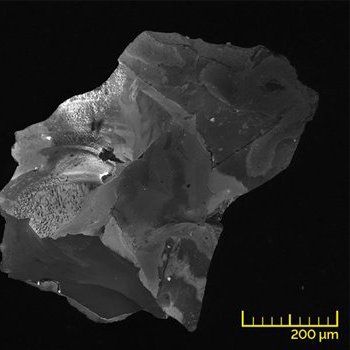

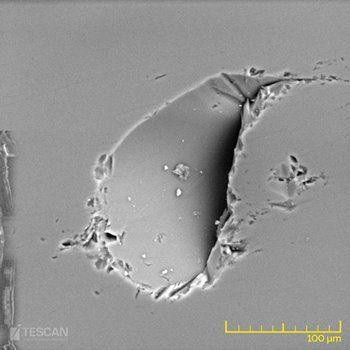

TESCAN AMBER

FIB-SEM nanoanalítico versátil para ampliar sus capacidades de investigación de materiales.

TESCAN SOLARIS

Banco de trabajo de nanofabricación avanzada para su laboratorio de investigación.

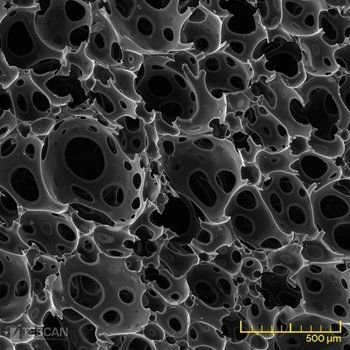

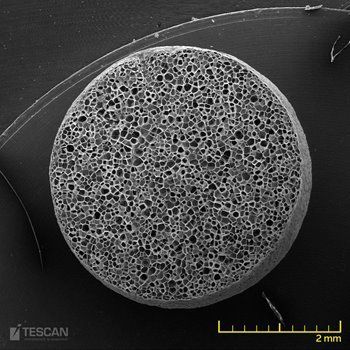

TESCAN AMBER X

Una combinación única de Plasma FIB y UHR FE-SEM sin campo para la caracterización de materiales multi-escala.

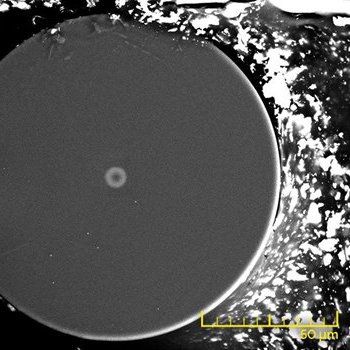

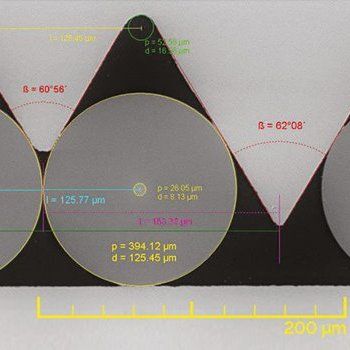

TESCAN UNITOM

Un micro-CT de resolución múltiple optimizado para un alto rendimiento, diversos tipos de muestras y flexibilidad para su investigación

TESCAN RAMAN SEM

TESCAN RISE combina la microscopía con focal Raman con la microscopía SEM (RISE) en un sistema de microscopio integrado.