CRESSINGTON

Cressington Vacuum Coating Systems

Zeppelin Metrology SL is the exclusive distributor of the complete line of high quality compact desktop vacuum coating systems manufactured by Cressington Scientific Instruments. Cressington's product range includes 108 series sputter coaters for standard SEM sample coating, 108 series carbon coaters for standard EDS coating, 208HR high resolution turbo sputter coaters for broadcast SEM applications (FESEM) and 208C High Vacuum Turbo Carbon Coaters for TEM/EBSD/EPMA Applications.

Dedicated thickness gauge systems offer precise control over the desired coating thickness. A rotating tilting stage allows for better uniformity and more conformal coating on topographic samples or the coating of a larger number of samples.

CRESSINGTON Products

Metallizer for SEM 108 Manual

Ideal for sample preparation for scanning electron microscopy.

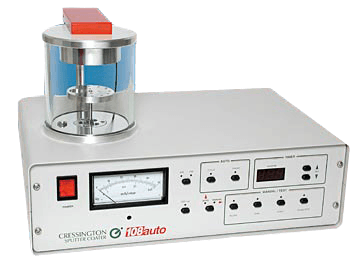

Automatic metallizer SEM 108 Auto

Ideal for sample preparation for scanning electron microscopy.

Cressington 108 Manual

Metallizer for SEM 108 Manual

Product description

This is an easy to use basic instrument for gold plating of SEM samples. It has fully variable current control, a digital process timer with pause option, a variable height sample table, a hinged top plate, and an O-ring sealed vacuum chamber. The control allows the spray current to be set independently of the gas pressure, which is adjusted separately by means of a manual leak valve. Coverage and grain size are optimized for any sample. Cool magnetron type head with 57mm diameter objective provides efficient spraying with minimal heating. The coating time is set by a timer with a digital readout and stored in memory. Vacuum status and sputtering current are displayed on the panel meter.

A modular desktop design combines the spray control unit, pumping system and thickness monitor in an area of just 400 x 600mm. It is fully integrated via a quick release all-metal coupling system. The height-adjustable specimen table will accept up to 12 pin-type tips or can be used as a platform for other types of tips and samples. A vacuum feed is provided for the optional film thickness monitor.

Chamber size: 120 x 120mm

Features and specifications

TECHNICAL DATA

| Chamber size | 120 mm Ø x 120 mm de alto (4,75" x 4,75") |

|---|---|

| Sputtering head | low-voltage planar magnatron |

| Quick change of destination | |

| Dark Space Surround Shield | |

| Gold installed as standard (Au / Pd or Pt optional) | |

| 57 mm Ø x 0.1 mm thick | |

| Sputter Supply | microprocessor based |

| safety interlocked | |

| Vacuum independent current control | |

| Variable 10 - 40mA | |

| Sample table | Holds 12 ½" SEM terminals |

| Height adjustment via 60 mm | |

| Empty, ATM - 0.001mb | |

| Current, 0 - 50mA | |

| Control method | Manual control of gas and current |

| Digital timer, 5 - 300 seconds with pause | |

| manual ventilationmanual ventilation | |

| Dimensions | Ancho 420 mm (16.5 "), Fondo 295 mm (11.6"), Alto 287 mm (11.3 ") |

| Weight | 10kg (22.1lbs) |

| Energy | 40VA max. (excluding rotary pump) |

| PUMPING SYSTEM | |

|---|---|

| Rotary pump | High speed, 2-stage direct drive |

| Pumping speed | 2.5 / 3.0 m 3 / h (50/60 Hz) |

| The pumpdown time at 0.1mb is 30/25 sec. | |

| The vacuum pump is mounted on a desktop compatible anti-vibration table | |

| All Metal Vacuum Coupling System | |

| Dimensions | Width 330mm (13.0"), Depth 215mm (8.5"), |

| H 210 mm (8,3"), 270 mm (10,6") con filtro | |

| Weight | 15kg (33.2lbs) |

| Energy | 130VA |

| REQUIRED SERVICES | |

|---|---|

| Supply | 100 - 120 or 200 - 240 VAC, 50/60 Hz (specify when ordering) |

| Energy | 170VA max. |

| Argon gas | Purity, min. 99.9% |

| Pressure, regulated 7 - 8 psi (0.5 - 0.6 bar) | |

| Hose connection, 6.0 mm (¼") |

Cressington 108 Auto

Automatic metallizer SEM 108 Auto

Product description

A more advanced spray coater where the entire sequence of flushing, leaking, coating and venting is automatically controlled. Solenoid operated blow off valve allows gas pressure to automatically return to preset conditions. The coater can also be operated in manual mode if required. The spray current is set by a digital programmer and is independent of gas pressure. Sputtering currents of up to 40 mA allow the magnetron head to efficiently bombard a variety of target materials. The coating time can be set, stored and displayed by the digital timer.

Further automation can be achieved with the addition of the finishing film thickness monitor. With this installed, the desired thickness can be entered and the sputtering process ends automatically when this thickness is reached.

Chamber size: 120 x 120 mm.

Features and specifications

| TECHNICAL DATA | |

|---|---|

| Sputtering head | Low-voltage planar magnetron type with fast target switching, wrap-around dark space shield |

| Sputtering target | ø57 x 0.1mm gold objective fitted as standard. Optional objectives: Au/Pd, Pt, Pt/Pd, Ag 57 mm diameter. x 0.1mm thick or 57mm diameter. x 0.2mm thick |

| Sputter Supply | Programmable digital control, microprocessor based, safety interlock, vacuum independent current control, 10 - 40 mA |

| Sample table | Holds 12 ½” (12.5mm) SEM terminals supplied as standard, height adjustment up to 60mm. RT and RPT stage. |

| Vacuum: atmosphere - 0.001mb, Current: 0 - 50mA | |

| Dimensions (W x D x H) | 420 mm x 295 mm x 287 mm |

| Weight | 11kg |

| Energy | 45VA max. (excluding rotary pump) |

| Pumping system speed | 3.0/3.6m3/h (50/60Hz). Pump idle time at 0.1MB is 20/25 seconds |

| The vacuum pump is mounted on a worktable compatible anti-vibration table with a stainless steel bellows coupling system | |

| Dimensions of the pumping system (W x D x H) | 330 mm x 215 mm x 210 mm (270 mm con filtro) x 210 mm |

| Weight of the pumping system | 15kg |

| Pumping system power | 130VA |

| SPECIFICATIONS | |

|---|---|

| Chamber size | 120 mm (4.75 ") in diameter x 120 mm (4.75") high |

| Gold blank ø 57 x 0.1 mm fitted as standard. | |

| Optional objectives: Au/Pd, Pt, Pt/Pd, Ag 57 mm diameter. x 0.1mm thick or 57mm diameter. x 0.2mm thick | |

| Sample table | Holds 12 ½” (12.5mm) SEM terminals supplied as standard, height adjustment up to 60mm. RT and RPT stage |

| Sputter Supply | Programmable digital control, microprocessor based |

| safety interlocked | |

| Vacuum independent current control, 10 - 40mA | |

| Sputtering head | Low-voltage planar magnetron type with fast target change |

| Dark Space Surround Shield | |

| Void: atmosphere - 0.001mb | |

| Current: 0 - 50mA | |

| Control method | Automatic operation of purge and gas leak functions |

| Automatic process sequencing | |

| Full Manual Override | |

| Digital timer (0-300 sec) with pause | |

| automatic ventilation | |

| Dimensions | 420mm wide x 295mm deep x 287mm high |

| Weight | 11kg |

| Power | 45VA max. (excluding rotary pump) |

| PUMPING SYSTEM | |

|---|---|

| Rotary pump | High speed, direct drive, 2 stage |

| Pumping speed | 3.0 / 3.6 m 3 / h (50/60 Hz) |

| Pump idle time at 0.1 Mb is 20/25 seconds | |

| Table system | Vacuum pump is mounted on a table compatible anti-vibration table with stainless steel bellows coupling system |

| Dimensions | 330mm Width x 215mm Depth x 210mm (270mm with filter) x Height 210mm |

| Weight | 15kg |

| Energy consumption | 130VA |

| REQUIRED SERVICES | |

|---|---|

| Supply | 100 – 120 or 200 – 240 VAC, 50/60 Hz (specify when ordering) |

| Energy | 175VA max. |

| Argon gas | min purity 99.9% |

| Pressure: Regulated 7 – 8 psi (0.5 – 0.6 bar) | |

| Hose connection: 6.0mm (1/4") |

| Thickness monitors (optional) | |

|---|---|

| Overall Specification | 4 digit display, push button zero |

| 6 MHz crystal with verification for life | |

| 10/s update rate | |

| Thickness range | LESS 99.9nm to 999.9nm |

| Resolution | better than 0.1nm |

| 0,50-30,00 g/cm 3 | |

| Tool Factor Range: | 0.25-8.0 |

| Lifetime display, change from 0.0 to 999.9 kHz | |

| Setting parameters | Non-volatile parameter memory with automatic acceleration of travel speed |

| Ease of data change | Memory of 2 sources (for example, Au sputtering and C evaporation) |

| Supply | 100 - 120 or 200 - 240 V AC at 4 VA, 50/60 Hz |

| Dimensions | Width 208mm (8.2"), Height 76mm (3.0"), Depth 160mm (6.3") |

| Weight | 1.7kg (3.75lbs) |

| Termination Installation | Enable/disable button |

| Termination Range | 0 - 999,9nm |

| Termination output | SPCO relay contact, no voltage rating 0.5 A at 110 V AC, 1 A at 24 V DC |

Cressington 108 Auto / SE

Large Metallizer for SEM 108 Auto/SE

Product description

A more advanced spray coater where the entire sequence of flushing, leaking, coating and venting is automatically controlled. Solenoid operated blow off valve allows gas pressure to automatically return to preset conditions. The coater can also be operated in manual mode if required. The spray current is set by a digital programmer and is independent of gas pressure. Sputtering currents of up to 40 mA allow the magnetron head to efficiently bombard a variety of target materials. The coating time can be set, stored and displayed by the digital timer.

Further automation can be achieved with the addition of the finishing film thickness monitor. With this installed, the desired thickness can be entered and the sputtering process ends automatically when this thickness is reached.

Camera size: 150 x 165mm.

Features and specifications

| TECHNICAL DATA | |

|---|---|

| Sputtering head | Low-voltage planar magnetron type with fast target switching, wrap-around dark space shield |

| Sputtering target | ø57 x 0.1mm gold objective fitted as standard. Optional objectives: Au/Pd, Pt, Pt/Pd, Ag 57 mm diameter. x 0.1mm thick or 57mm diameter. x 0.2mm thick |

| Sputter Supply | Programmable digital control, microprocessor based, safety interlock, vacuum independent current control, 10 - 40 mA |

| Sample table | Holds 12 ½” (12.5mm) SEM terminals supplied as standard, height adjustment up to 60mm. RT stage available for RPT stage |

| Vacuum: atmosphere - 0.001mb, Current: 0 - 50mA | |

| Dimensions (W x D x H) | 420 mm x 295 mm x 287 mm |

| Weight | 11kg |

| Energy | 45VA max. (excluding rotary pump) |

| Pumping system speed | 3.0/3.6m3/h (50/60Hz). Pump idle time at 0.1MB is 20/25 seconds |

| The vacuum pump is mounted on a worktable compatible anti-vibration table with a stainless steel bellows coupling system | |

| Dimensions of the pumping system (W x D x H) | 330 mm x 215 mm x 210 mm (270 mm con filtro) x 210 mm |

| Weight of the pumping system | 15kg |

| Pumping system power | 130VA |

| PUMPING SYSTEM | |

|---|---|

| Rotary pump | High speed, direct drive, 2 stage |

| Pumping speed | 3.0 / 3.6 m 3 / h (50/60 Hz) |

| Pump idle time at 0.1 Mb is 20/25 seconds | |

| Vacuum pump is mounted on a table compatible anti-vibration table with stainless steel bellows coupling system | |

| Dimensions | 330mm Width x 215mm Depth x 210mm (270mm with filter) x Height 210mm |

| Weight | 15kg |

| Energy consumption | 130VA |

| REQUIRED SERVICES | |

|---|---|

| Supply | 100 – 120 or 200 – 240 VAC, 50/60 Hz (specify when ordering) |

| Energy | 175VA max. |

| argon gas | min purity 99.9% |

| Pressure: Regulated 7 – 8 psi (0.5 – 0.6 bar) | |

| Hose connection: 6.0mm (1/4") |

| Thickness monitors (optional) | |

|---|---|

| Overall Specification | 4 digit display, push button zero |

| 6 MHz crystal with verification for life | |

| 10/s update rate | |

| Thickness range | LESS 99.9nm to 999.9nm |

| Resolution | better than 0.1nm |

| 0,50-30,00 g/cm 3 | |

| Tool Factor Range: | 0.25-8.0 |

| Lifetime display, change from 0.0 to 999.9 kHz | |

| Setting parameters | Non-volatile parameter memory with automatic acceleration of travel speed |

| Ease of data change | Memory of 2 sources (for example, Au sputtering and C evaporation) |

| Supply | 100 - 120 or 200 - 240 V AC at 4 VA, 50/60 Hz |

| Dimensions | Width 208mm (8.2"), Height 76mm (3.0"), Depth 160mm (6.3") |

| Weight | 1.7kg (3.75lbs) |

| Termination Installation | Enable/disable button |

| Termination Range | 0 - 999,9nm |

| Termination output | SPCO relay contact, no voltage rating 0.5 A at 110 V AC, 1 A at 24 V DC |

Cressington 208HR

Turbo Metallizer for FESEM 208HR

Product description

The Cressington 208HR High Resolution Sputter Coater offers a real solution to the problems encountered when coating difficult samples for FEG SEM imaging.

To minimize the effect of grain size, the coater provides full control over thickness and deposition conditions. The turbomolecular entrainer pump provides the high vacuum needed for non-noble metal sputtering while having excellent gas handling characteristics. The magnetron sputtering head has the high current capability required for chrome sputtering and a source shutter for target conditioning is provided as standard.

The tilting rotating planetary stage ensures that highly contoured samples are evenly coated. This ensures that the minimum coating thickness can be applied to provide conductivity without compromising the fine details of the sample. The double height 150mm diameter working chamber provides easy adjustment of the working distance.

The built-in finish film thickness monitor allows close monitoring and reproduction of coating thickness for repeated samples.

Features and specifications

| TECHNICAL DATA | |

|---|---|

| Sputtering head | Low-voltage planar magnetron type with fast target switching, wrap-around dark space shield |

| ø57 x 0.1mm gold objective fitted as standard. Optional objectives: Au/Pd, Pt, Pt/Pd, Ag 57 mm diameter. x 0.1mm thick or 57mm diameter. x 0.2mm thick | |

| Sputter Supply | Programmable digital control, microprocessor based, safety interlock, vacuum independent current control, 80 mA max. |

| Sample table | Motorized Rotating Planetary Stage with Manual Tilt (Standard) |

| Analog measurement | Vacuum: atmosphere - 0.001mb, current: 0 - 100mA |

| Dimensions (W x D x H) | 600 mm x 600 mm x 450 mm |

| Weight | 40kg |

| Energy | 550VA max. |

| Pumping system speed | 550VA max. |

| Table system | The vacuum pump is mounted on a worktable compatible anti-vibration table with stainless steel bellows coupling system |

| SPECIFICATIONS | |

|---|---|

| Chamber size | 150 mm in diameter x 250 mm high |

| 150 mm in diameter x 165 mm high | |

| ø57mm. Opcional Cr, Ta, Au, Au / Pd, Pt, W, Ir, Ag | |

| Blank conditioning shutter included as standard. | |

| Sample table | Motorized Rotating Planetary Stage with Manual Tilt (Standard) |

| Manual tilt 0 - 90° | |

| 4 sample boards supplied as standard (specify when ordering) | |

| Sputter Supply | Programmable digital control, microprocessor based |

| safety interlocked | |

| Vacuum independent current control, 80mA max. | |

| Sputtering head | Low-voltage planar magnetron type with fast target change |

| Dark Space Surround Shield | |

| Void: atmosphere - 0.001mb | |

| Current: 0 - 100mA | |

| Control method | Automatic operation of purge and gas leak functions |

| Automatic process sequencing | |

| Full Manual Override | |

| Digital timer (0-300 sec) with pause | |

| automatic ventilation | |

| Thickness monitoring | Film thickness monitor for Agar SEM Turbo Coater (AGB7240) included as standard |

| Dimensions | Width 600mm (23.6"), Depth 600mm (23.6"), Height 450mm (17.7") |

| Weight | 40kg |

| Power | 550VA max. |

| PUMPING SYSTEM | |

|---|---|

| Setting | Combination turbo-entrainment/rotary pump. Optional diaphragm pump instead of rotary pump |

| Pumping speed | 300 liters / min and 0.1 MB |

| Pump idle time | 1 minute. at 1x10 -3 mb (1.5 min. with diaphragm pump option) |

| Maximum pressure | 1x10 -5 mbar |

| Table system | Vacuum pump is mounted on a table compatible anti-vibration table with stainless steel bellows coupling system |

| REQUIRED SERVICES | |

|---|---|

| Supply | 100 – 120 or 200 – 240 VAC, 50/60 Hz (specify when ordering) |

| Energy | 175VA max. |

| argon gas | min purity 99.9% |

| Pressure: Regulated 7 – 8 psi (0.5 – 0.6 bar) | |

| Hose connection: 6.0mm (1/4") |

| Thickness monitors (optional) | |

|---|---|

| Overall Specification | 4 digit display, push button zero |

| 6 MHz crystal with verification for life | |

| 5/s update rate | |

| Thickness range | Omn a 999.9nm |

| Resolution | better than 0.1nm |

| Density range | 0,50-30,00 g/cm 3 |

| Tool Factor Range: | 0.25-8.0 |

| 0mn a 999,9 kHz |

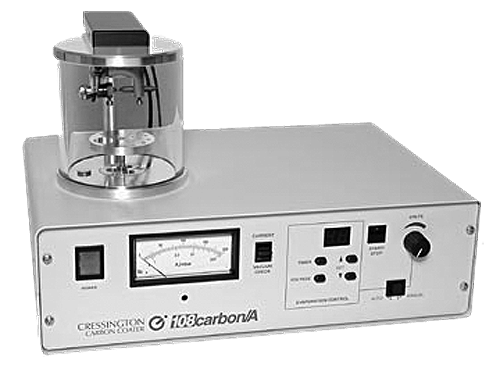

Cressington 108C Auto

Automatic carbon evaporator SEM 108C Auto

Product description

The 108C Auto Carbon SEM Coater is a unit dedicated to the routine coating of SEM and microprobe samples, where a low atomic number conductive coating is required. Dual carbon rod source with unique current feedback control provides highly reproducible carbon coatings.

In automatic mode, the required voltage setting and flash time can be entered and displayed through the digital programmer. Manual and pulse modes are also included for coating heat-sensitive samples. The height-adjustable sample table allows the working distance to be changed.

When accurate determination of coating thickness is required, the manual film thickness monitor can be used with this coating unit and a vacuum step is included for this purpose.

Chamber size: 120mm diameter x 120mm

Features and specifications

| TECHNICAL DATA | |

|---|---|

| Chamber size | 120mm Ø x 120mm alto |

| Bradley type (Ø 6.15mm rods), heavy duty stainless steel construction | |

| Sample table | Holds 12 ½" SEM terminals, height adjustment up to 60mm |

| Weight | 14kg |

| Dimensions (W x D x H) | 420x295x287mm |

| Energy | 800VA max. |

| Rotary pump | High speed, 2-stage direct drive, pump time at 0.1MB is 20/25 seconds |

| Desktop system | Vacuum pump is mounted on a desktop compatible anti-vibration table, all metal vacuum coupling system |

| Vacuum pump dimensions | 330 x 215 x 210 mm (H 270 mm con filtro) |

| Vacuum pump weight | 15kg |

| Vacuum pump power | 130VA |

| SPECIFICATIONS | |

|---|---|

| Chamber size | 120 mm in diameter x 120 mm high (4.75 "x 4.75") |

| Bradley type (6.15 mm diameter rods) | |

| Heavy duty stainless steel construction. | |

| Evaporation Supply | microprocessor based |

| Feedback loop controlled with remote current/voltage sensing | |

| safety interlocked | |

| Variable, 135A max. with overcurrent protection | |

| Sample table | Capacity for 12 SEM checks |

| Height adjustment via 60 mm | |

| Empty, ATM - 0.001mb | |

| Current, 0 - 200A | |

| Control method | Automatic evaporation control using programmed voltage and timer |

| Full manual override with pulsed or continuous operation | |

| Digital timer, 1 - 30 seconds | |

| Digital voltage adjustment, 0.1 - 5.5V | |

| automatic ventilation | |

| Thickness monitoring | Optional, MTM-10 only |

| Dimensions | Width 420mm (16.5"), Depth 295mm (11.6"), Height 287mm (11.3") |

| Weight | 14kg (30.9lbs) |

| Energy | 800VA max. (excluding rotary pump) |

| PUMPING SYSTEM | |

|---|---|

| Rotary pump | High speed, 2-stage direct drive |

| Pumping speed | 3.0 / 3.6 m 3 / h (50/60 Hz) |

| Pumpdown time at 0.1mb is 20/25 sec. | |

| The vacuum pump is mounted on a desktop compatible anti-vibration table | |

| All Metal Vacuum Coupling System | |

| Dimensions | Width 330mm (13.0"), Depth 215mm (8.5"), Height 210mm (8.3"), 270mm (10.6") with filter |

| Weight | 15kg (33.2lbs) |

| Energy | 130VA |

| REQUIRED SERVICES | |

|---|---|

| Supply | 100 – 120 or 200 – 240 VAC, 50/60 Hz (specify when ordering) |

| Energy | 930VA max. |

Cressington 108C Auto/SE

Large automatic carbon evaporator SEM 108C Auto

Product description

The 108C Auto Carbon SEM Coater is a unit dedicated to the routine coating of SEM and microprobe samples, where a low atomic number conductive coating is required. Dual carbon rod source with unique current feedback control provides highly reproducible carbon coatings.

In automatic mode, the required voltage setting and flash time can be entered and displayed through the digital programmer. Manual and pulse modes are also included for coating heat-sensitive samples. The height-adjustable sample table allows the working distance to be changed.

When accurate determination of coating thickness is required, the manual film thickness monitor can be used with this coating unit and a vacuum step is included for this purpose.

Chamber size: 150mm diameter x 165mm

Features and specifications

| TECHNICAL DATA | |

|---|---|

| Chamber size | 150mm Ø x 165mm alto |

| Bradley type (Ø 6.15mm rods), heavy duty stainless steel construction | |

| Sample table | Holds 12 ½" SEM terminals, height adjustment up to 60mm |

| Weight | 14kg |

| Dimensions (W x D x H) | 420x295x287mm |

| Energy | 800VA max. |

| Rotary pump | High speed, 2-stage direct drive, pump time at 0.1MB is 20/25 seconds |

| Vacuum pump is mounted on a desktop compatible anti-vibration table, all metal vacuum coupling system | |

| Vacuum pump dimensions | 330 x 215 x 210 mm (H 270 mm con filtro) |

| Vacuum pump weight | 15kg |

| Vacuum pump power | 130VA |

| SPECIFICATIONS | |

|---|---|

| Chamber size | 150 mm in diameter x 165 mm high (4.75 "x 4.75") |

| Bradley type (6.15 mm diameter rods) | |

| Heavy duty stainless steel construction. | |

| Evaporation Supply | microprocessor based |

| Feedback loop controlled with remote current/voltage sensing | |

| safety interlocked | |

| Variable, 135A max. with overcurrent protection | |

| Sample table | Capacity for 12 SEM checks |

| Height adjustment via 60 mm | |

| Empty, ATM - 0.001mb | |

| Current, 0 - 200A | |

| Control method | Automatic evaporation control using programmed voltage and timer |

| Full manual override with pulsed or continuous operation | |

| Digital timer, 1 - 30 seconds | |

| Digital voltage adjustment, 0.1 - 5.5V | |

| automatic ventilation | |

| Optional, MTM-10 only | |

| Dimensions | Width 420mm (16.5"), Depth 295mm (11.6"), Height 287mm (11.3") |

| Weight | 14kg (30.9lbs) |

| Energy | 800VA max. (excluding rotary pump) |

| PUMPING SYSTEM | |

|---|---|

| Rotary pump | High speed, 2-stage direct drive |

| Pumping speed | 3.0 / 3.6 m 3 / h (50/60 Hz) |

| Pumpdown time at 0.1mb is 20/25 sec. | |

| Desktop system | The vacuum pump is mounted on a desktop compatible anti-vibration table |

| All Metal Vacuum Coupling System | |

| Dimensions | Width 330mm (13.0"), Depth 215mm (8.5"), Height 210mm (8.3"), 270mm (10.6") with filter |

| Weight | 15kg (33.2lbs) |

| Energy | 130VA |

| REQUIRED SERVICES | |

|---|---|

| Supply | 100 – 120 or 200 – 240 VAC, 50/60 Hz (specify when ordering) |

| Energy | 930VA max. |

Cressington 208C

Turbo Carbon Evaporator TEM 208C

Product description

High vacuum carbon evaporation provides the predictable spatial distribution and thickness needed for X-ray microanalysis and imaging of non-conducting samples. High vacuum is achieved by a 80 l/sec turbomolecular pump backed by a rotary pump. In addition to providing fast pump downtime, it has the advantage of not requiring water cooling or a long warm-up period. The vacuum is continuously monitored. Carbon is dual-evaporated from the carbon rod source with manual, pulsed or automatic mode operation. The thickness can be monitored by the optional film thickness monitor.

For highly contoured samples, the optional motorized rotating planetary stage with tilt greatly increases sample coverage. All four sample holders are interchangeable and can be configured to fit most types of samples or metallurgical setups. Up to 24 pin tips can be coated at one time. The stage includes a lower working chamber. This allows the working distance to be changed. The long working distance with the standard 150mm diameter x 150mm high chamber with 0° tilt can be used for uniform coating of flat polished microprobe samples, while the short working distance with the high tilt is used for topographic samples.

This is the most advanced carbon coater with wide applications for TEM, SEM and microprobe techniques. The basic turbo carbon coater can be equipped with different accessories to make it suitable for SEM (with high vacuum for microprobe or polished substrates, or low vacuum for coarse or granular substrates), TEM (for support films, shadowing, aperture cleaning, glow discharge, etc.) or both.

The modular design allows quick changeover between a variety of applications with optimized operating conditions:

- Voltage controlled wand source provides multiple evaporation capability Automatic evaporation control provides ease of use in a busy environment Low cost thickness monitor provides reproducible results 80 l/s turbo pump in a 150mm chamber provides a very fast emptying Reduces operating costs by not having a diffusion pump, water cooling or liquid nitrogen

Features and specifications

Technical specifications

Double height sample chamber: 150mm diameter x 150mm height and 150mm diameter x 65mm height

vacuum system

Integrated desktop pumping system

- 801/sec Turbomolecular PumpTwo Stage Rotary PumpPirani Gauge (ATM - 0.001Mb)Penning Gauge (10 -2 to 5 x 10 -6 )Precision Needle ValveAll Metal Pumping Lines

Carbon evaporation source

6.5mm carbon rod double source.

- Feedback controlled voltage supply, current measurement 0-200A Automatic/manual operation Pulse/continuous mode selection Digital timer

rotary planetary stage

Motorized table with 4-position rotating planetary movement with 4 supports.

- Speed Controller - 4 Speed 0-90° Tilt Mounting Collar

Film thickness monitor control unit

- Oscillator crystal head and wires Thickness range 0-999.9nm

Overall dimensions: 524mm wide x 295mm deep

Occupied bench space (including rotary pump): 525mm wide x 600mm deep

Weight: 45kg