LUXOR

The revolutionary metallic coating.

Fully automated spray coater for the most reliable and homogeneous coating of metal samples.

A TECHNOLOGY A²

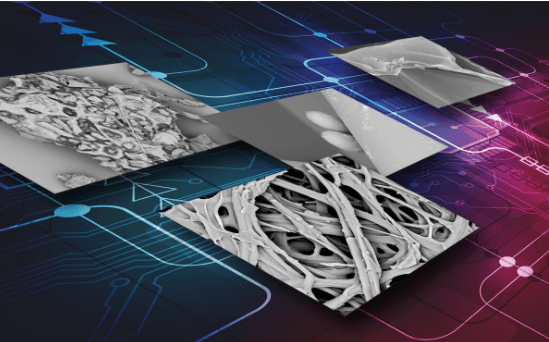

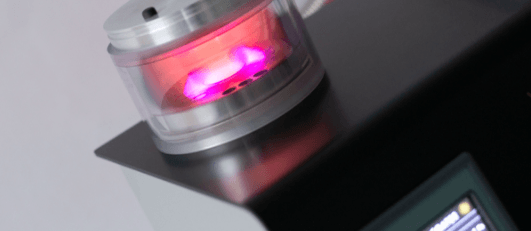

LUXOR's unique A² technology generates a metallic plasma and applies it in a controlled and precise manner, resulting in an extremely smooth, thin and homogeneous layer of gold. This is achieved by creating a vacuum in the process chamber, after which a high voltage is applied.

The coating current is then automatically regulated by the addition of small amounts of process gas into the reactor, until the set target current is reached and stabilized.

The unique way this process is controlled and adjusted is what sets LUXOR metal coaters apart from other instruments on the market. For the SEM operator, this means more homogeneous metal coatings, resulting in high-resolution, high-contrast images and a worry-free, hands-free coating process.

LUXOR Products

LUXOR Au

The LUXOR Au is an advanced, fully automated sputtering device that applies a fine grain gold coating from 1 to 100 nm thick.

LUXOR Pt

The LUXOR Pt is a highly innovative, fully automated sputtering device that applies a fine-grain platinum or gold coating from 1 to 100 nm thick.

LUXOR Au

The LUXOR Au is an advanced, fully automated sputtering device that applies a fine grain gold coating from 1 to 100 nm thick. This allows you to obtain the best SEM image quality of your samples.

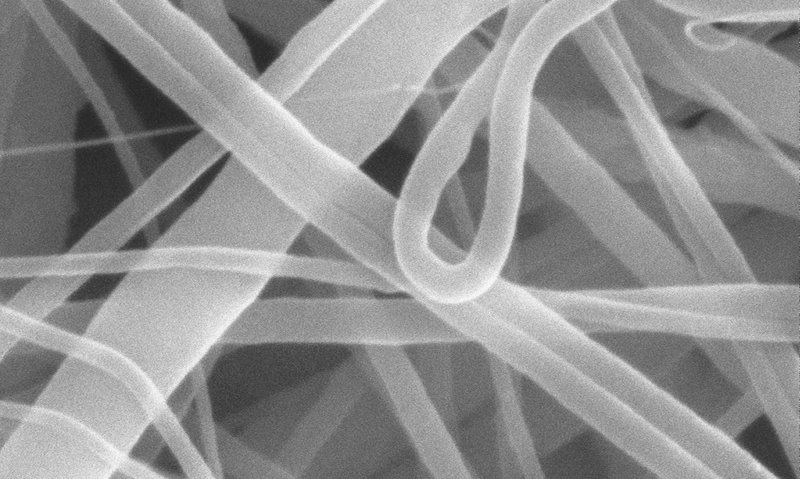

LUXOR's unique A² technology creates a controlled plasma in the process gas. In the plasma, the ions are accelerated by high voltage and directed towards the gold target. The finest gold atom clusters are released from the target and precisely coat your samples, resulting in an extremely uniform, thin and homogeneous layer of gold.

The LUXOR Au is also known for its ease of use and fast, hassle-free operation.

TECHNOLOGY

LUXOR Au is typically used for SEM imaging applications up to 100,000x magnification where sample loading may be an issue, as the coating greatly reduces sample loading by increasing conduction.

The coater is designed to enhance secondary electron emission. As a result, the microscope's detectors will capture more detail from high-resolution images.

Another benefit is reduced beam penetration, which significantly improves edge resolution. Furthermore, this prevents sensitive samples from being damaged.

Profits

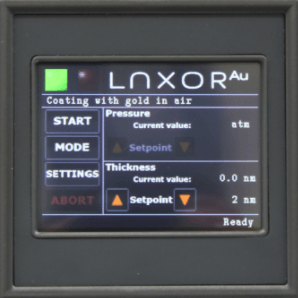

OPTIMIZED USER INTERFACE

First of all, the LUXOR Au is remarkably easy to use. Using the built-in touch screen, the coating process can be started with just a few clicks.

SUPERIOR GOLD PLATING RESOLUTION

Field tests clearly show that LUXORAu generates smaller, more homogeneous gold grains compared to other plating instruments on the market. In addition, A² technology guarantees identical and reproducible coating results, day after day and year after year.

INCREASED SPEED AND EFFICIENCY

The LUXOR Au can process up to six samples at one time. And while the gold plating procedure is very precise, it's also remarkably fast.

ADVANCED SEM PROTECTION

LUXOR Au's unique "upside down" design ensures that loose particles are removed during the plating process. In this way, your SEM is optimally protected.

ROBUST DESIGN, MADE IN GERMANY

Despite its modest size and elegant appearance, the LUXOR Au is a robust and sturdy device. It is designed to be used intensively and to work without problems for many years.

Features and specifications

- Vacuum and drying modes: 7 Pa to 150 Pa (continuously selectable) Process time: 1 to 600 minutes (continuously selectable) Gold layer thickness: 1 to 100 nm (continuously selectable) Processing chamber: Borosilicate glass Ø 100 mm x 150 mm height Implosion shield: PET Ø 120 mm x 150 mm height Vacuum connector: DN 16 KF Gas supply: Air or argon (0.6 bar) Dimensions: 340 x 340 x 290 (mm, width x depth x height )Weight: 11kg

- Au plating with air or argon Maximum capacity: 7 x Ø 12.5 mm or 3 x Ø 25 mm stubs Average plating time: 5 minutes (based on 10 nm gold plating) Additional vacuum and drying modes Two stage pump low energy

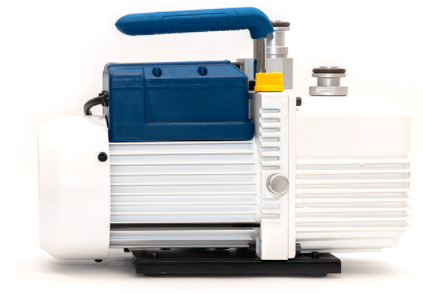

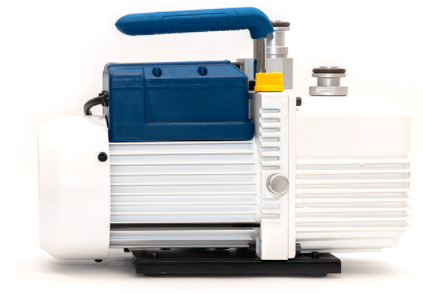

VACUUM PUMP

Can be ordered separately as a "pump kit" which includes:

- Two-stage suction pump with a pumping capacity of 4.8 m³/h Metal vacuum hose, DN 16 KF, length 1 m2 unions and 2 gaskets DN 16 KF1 oil mist filter.energy

LUXOR Pt

The LUXOR Pt is a highly innovative, fully automated sputtering device that applies a fine-grain platinum or gold coating from 1 to 100 nm thick.

LUXOR's unique A² technology ensures that the gold or platinum is sprayed in a highly controlled and precise manner, resulting in an extremely smooth, fine and homogeneous coating.

This allows your scanning electron microscope to display the best possible image quality.

TECHNOLOGY

Thanks to the advanced design of the sputter coater, there is no longer a need for a turbomolecular pump, which was traditionally a complicated and vulnerable part of any high-resolution platinum coater. Instead LUXOR Pt uses an efficient and robust double stage pump.

LUXOR Pt Metal Sputter Coater is primarily used for SEM (FEG) imaging applications up to 1000000x magnification where sample loading is an issue. The LUXOR Pt guarantees the coating of SEM samples with only a few nanometers of platinum or gold with an extremely small grain size. This results in sharp, clear SEM images.

The sputtering applicator is designed to enhance secondary electron emission, allowing the microscope's detectors to capture more detail from high-resolution images. Finally, reduced beam penetration improves edge resolution and prevents sensitive samples from being damaged.

With its advanced specifications and features, LUXOR Pt offers high productivity and is remarkably easy to use.

Profits

ADVANCED USER INTERFACE

Thanks to its user-friendly touch screen interface, the coating process can be started with just a few clicks.

UPPER LINING RESOLUTION

Research and field tests show that LUXOR Pt generates exceptionally homogeneous platinum and gold coatings compared to other platinum coating devices, while only using a robust two-stage pump. Furthermore, our A² technology ensures that coating results are consistent over a very long period of time.

SPEED AND EFFICIENCY

The LUXOR Pt processes your samples, up to six at a time, quickly and reliably, allowing for maximum productivity.

EXCELLENT PROTECTION SEM

Your scanning electron microscope is optimally protected, as the LUXOR Pt's unique "inverted" design ensures that loose particles are removed during the coating process. In this way, your SEM is optimally protected.

ROBUST DESIGN, MADE IN GERMANY

Despite its modest size and elegant appearance, the LUXOR Pt is a robust and rugged device. It is designed to be used intensively and to function without problems for many years.

Features and specifications

- Vacuum and drying modes: 7 Pa to 150 Pa (continuously selectable) Au/Pt layer thickness: 1 to 100 nm (continuously selectable) Process time: 1 to 600 minutes (continuously selectable) Process chamber: Borosilicate glass Ø 100 mm x 150 mm height Implosion shield: PET Ø 120 mm x 150 mm height Vacuum connector: DN 16 KF Gas supply: Air or argon (0.6 bar) Dimensions: 340 x 340 x 290 (mm, width x depth x high)Weight: 12.5kg

- Plating of Pt or Au with air or argon Maximum capacity: 7 x Ø 12.5 mm or 3 x Ø 25 mm stubs Average coating time: 4 – 5 minutes (based on a platinum coating of 2 nm or 4 nm respectively) Average time coating time: 5 minutes (based on a 10 nm gold coating) Vacuum and drying modes Two-stage low-energy pump

VACUUM PUMP

Can be ordered separately as a "pump kit" which includes:

- Two-stage suction pump with a pumping capacity of 4.8 m³/h Metal vacuum hose, DN 16 KF, length 1 m2 unions and 2 gaskets DN 16 KF1 oil mist filter.energy